At our company, we leveraged the powerful capabilities of Ansys Fluent to enhance engineering simulations, particularly in understanding how water interacts with various components in our systems. By simulating fluid dynamics, we closely analyzed how water flows into pipes and tanks, behaves during tank descent, discharges from tanks, and the timing of these processes. Additionally, we obtained dynamic properties—such as velocity, volume and mass flow rates, and pressure—which were critical for optimizing system design. Ansys Fluent enabled detailed visualization of these interactions, allowing us to refine our models and ensure optimal performance under real-world conditions.

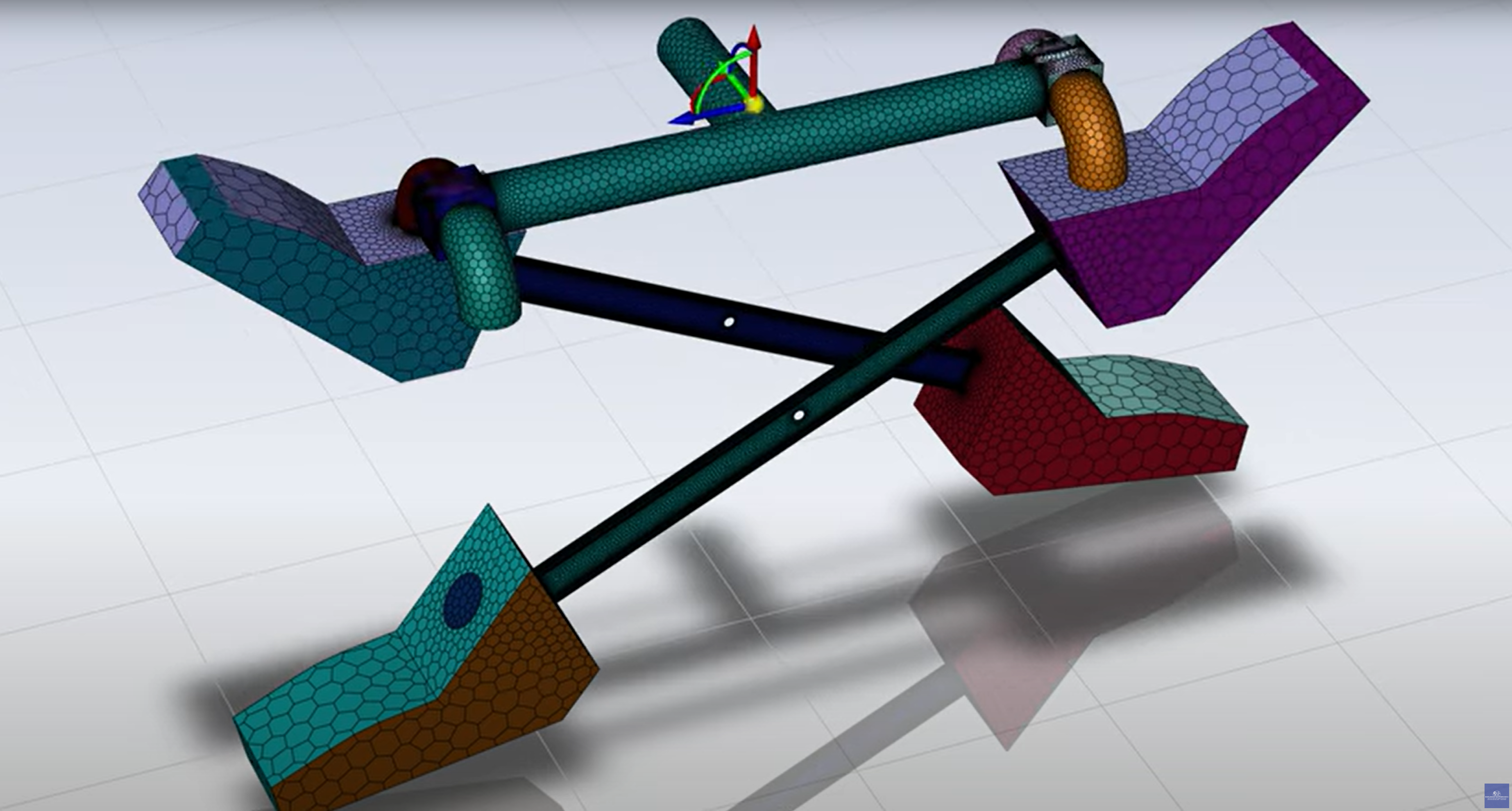

Accurate results heavily depended on mesh quality, and we used Ansys Fluent Meshing to achieve the required precision. We customized the meshing process using a poly-hexcore mesh structure, which offered a strong balance between accuracy and computational efficiency—especially for complex geometries involving solid and fluid regions. Mesh sizes were carefully tailored for both surface and volume meshes to align with the dimensions of the simulated objects. By assigning non-conformal meshing to all components, we ensured that even moving regions were accurately represented without interference between adjacent meshes.

In addition to meshing, we employed Ansys Fluent’s multiphase feature to simulate interactions between different phases—particularly air and water. This was essential since our systems often contained components initially filled with either air or water. Using the volume fraction method, we accurately modeled how these phases interacted within the system. We also implemented dynamic meshing and user-defined functions (UDFs) to simulate moving objects within our setup. This approach maintained realistic component interactions, ensuring the mesh adapted dynamically to system changes.

To further refine our simulations, we configured various parameters within Ansys Fluent. Solution methods and relaxation factors were set to ensure efficient convergence without compromising accuracy. The k-epsilon turbulence model was applied to account for the turbulent flows commonly present in our systems. We also used mesh interfaces to manage object connections, ensuring seamless interactions across boundaries. Boundary conditions—including inlets, outlets, and mesh interfaces—were meticulously defined to accurately simulate fluid flow and behavior.

Our use of Ansys Fluent in optimizing computational fluid dynamics has significantly advanced our ability to design and refine complex systems. By leveraging its powerful simulation tools—including advanced meshing techniques, multiphase analysis, and dynamic meshing—we gained a deep understanding of fluid interactions. This comprehensive approach enabled us to accurately predict and enhance design performance, ensuring both efficiency and reliability. As a result, our systems are now better optimized to meet real-world challenges and improve overall operational effectiveness.