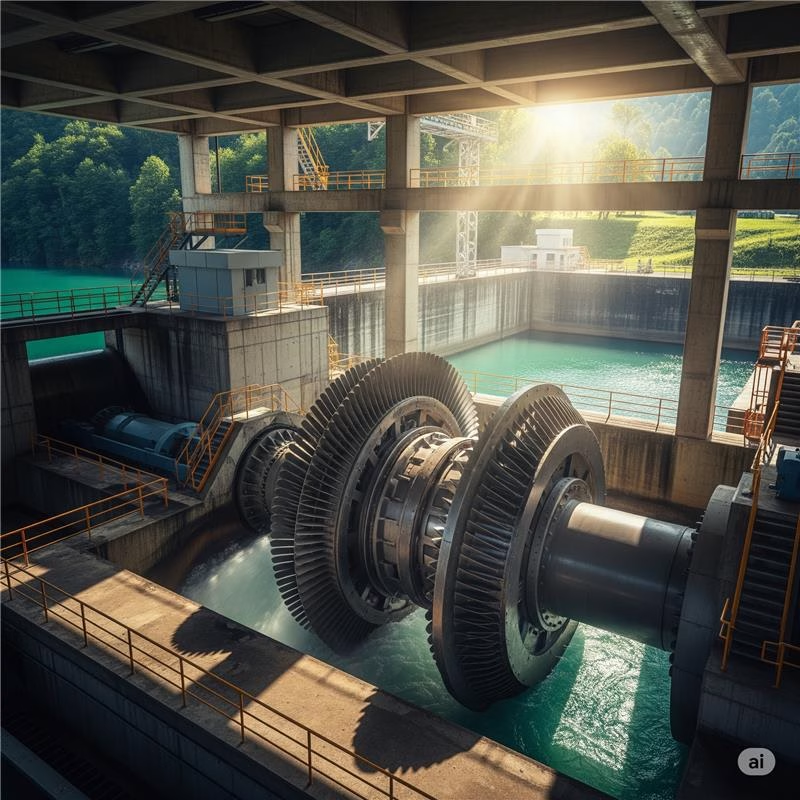

The conventional hydroelectric power plants convert the energy of water into electricity by directing the flow of water from great heights into a turbine; this means that an efficient energy conversion could be realized with high head and consistent flow.

The Eiselstein Energy Converter also uses water to generate electricity, but it does it more efficiently by using the weight of the water instead of flow and by using linear motion instead of rotary motion. It requires less footprint since the Eiselstein converter uses tanks to contain water instead of building dams. Its efficiency is also projected to be about 70%–85%, which is comparable to the typical efficiency range of commercial hydroturbines. The comparison of both energy converters is summarized in the table below:

| Feature | Traditional Hydroelectric Power Plant | Eiselstein Energy Converter |

| Motion | Rotary | Linear (up/down) |

| Equipment Efficiency | 70 – 90% | 70-85% (projected) |

| Plant/Capacity Factor* | 44% (global average) | 72% (projected) |

| Site Flexibility | Limited (highly dependent on head/flow based on pressure) | Broad (head/flow based on gravity/weight) |

| Environmental Impact | Moderate to High, Habitat Disruption | Minimal, Non-invasive |

| Maintenance | Complex, Underwater | Simple, Surface-accessible |

| Scalability | Site-specific | Modular, Array-based |

| Resource Utilization | Partial water cycle | Full water cycle |

| Innovation | Mature, incremental | Disruptive, transformative |

| Funding | Supported by DOE and private investments | Under US DOE EERE review, gaining recognition |

| AI / Emergency Use | Reliable for baseload if sited correctly but rapid deployment is less flexible than modular alternatives | Ideal for distributed, resilient, and rapid response needs |

*Ratio of the actual electrical energy produced by a generating unit over a certain period. A capacity factor of 100% means the plant was running at its maximum capacity all the time, while a lower percentage indicates the plant was operating below its full potential due to factors like maintenance, fuel availability, or variability in renewable resources.